FIRE RATED GLASS is a functional building fire resistance material that can efficiently control smoke and fire spread. They have been processed and treated in a special process to maintain its integrity and thermal insulation in the specified fire test.

Fire Performance Type:

Insulated Type Fire Resistance Glass ( Double Layer )

Double Layer Fire Resistance glass composed of two glass bonded by special type of fire gel surrounded by a special flame retardant tape. This meets the fire integrity and fire insulation requirements. This Glass gas light transmission, fire resistance( smoke resistance, fire insulation, shielding heat radiation ) sound insulation and impact resistance. Suitable for building decoration that require both clear view and fire proofing. Mostly use for outdoor applicaions.

Non – Insulated Fire Protective Glass ( Single Layer)

Use only to meet the fire integrity of the monolithic fire glass such as light transmission, fire and smoke. Applicable to no insulation requirements for the glass partition wall. Mostly use indoor.

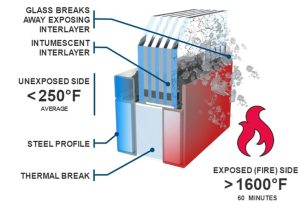

FIRE-PROTECTIVE VS. FIRE-RESISTIVE

Fire rated glazing can either be defined as fire-protective or fire-resistive. The lesser Fire Protective glazing defends against smoke and Flames whereas Fire Resistive glazing is more advanced in design and restricts the dangerous transmission of radiant heat.

Fire-protective glass does not provide protection from the dangers of radiant heat transfer. It is simply designed to protect against the spread of smoke and flames with an ability to achieve such protections that range from 20 to 180 minutes. As a result of its limitations, fire protective rated glazing is restricted by code to specific building application, area, and sizing limits.

Fire-resistive glass not only blocks smoke and flames but also provides a barrier to the dangers of heat. Tested similar to fire protective in terms of fire, hose stream, & impact – however it also must meet ASTM E119 – which is the standard method for fire rated wall construction. Because these products are tested to the same standard as a fire rated wall assemblies they are defined by the IBC as “transparent walls”.